What Is Direct To Garment Printing?

Digital printing is a relatively new printing technique where digital files are printed on textiles. The printing process is linked to computers and then transferred to a digital printer. The ink is sprayed across the textile to create the image, similar to printing with a desktop inkjet printer and paper.

There are various names for this process, including direct to garment printing, digital direct to garment printing, digital apparel printing and inkjet to garment printing. These are all synonyms and mean exactly the same. For this post, however, it will be referred to as DTG (or Direct To Garment).

The two main forms of textile printing are Silkscreen Printing and DTG printing, and each has there own pros and cons depending on the job. The main difference between the two is the process – whilst silkscreen requires an individual screen to be made per design (mulitple screens if there is more than one colour), DTG only requires a print file which can be switched out.

Ultimate Flexibility

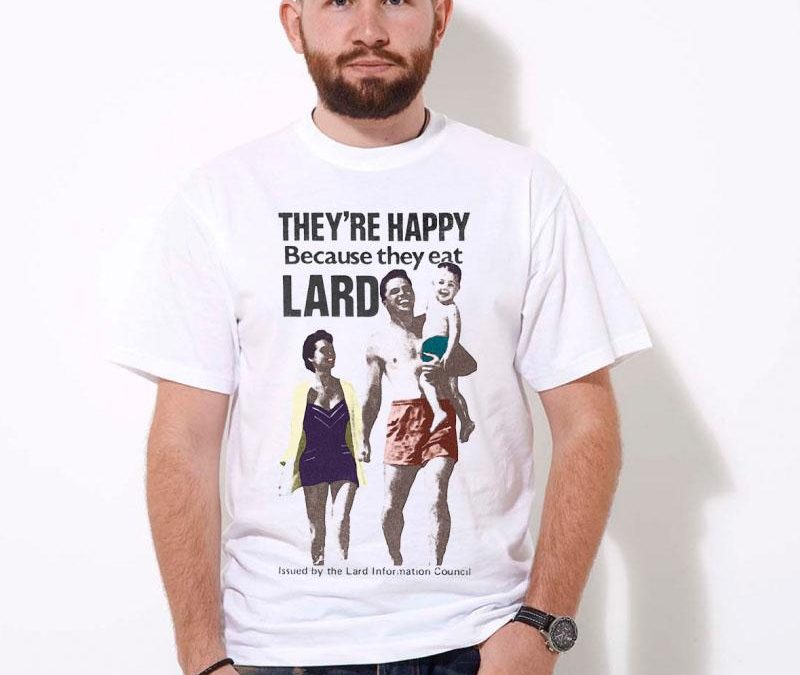

This difference means that what DTG does really well is provide flexibility, especially excelling with small to medium sized orders which have multiple designs. Although large orders can work out better for designs with multiple colours. MoreTVicar, a t-shirt company we work closely with, is perfect for DTG. Selling hundreds of individual designs, we can fulfill each order as and when each design is purchased. They can also offer a variety of coloured textiles/clothing too, however, the best results are certainly with a white textile.

With DTG printing, the ink goes in in the fibers. For white textile, the printing will be absolutely great. Coloured textiles/clothing will have to be pretreated to have colour inks. Thats why we always use an underlayer or a coating layer on coloured and black t-shirts. This is necessary to have a durable product and a great colour effect. If there is no coating layer, the print will disappear after a few washes. This is not a standard for every printing company, but its our standard to print an underlayer.

To see our printer in action check out this post here.

Designing For DTG

Carrying on the theme of flexibility, another pro for DTG is that there are less limitations in terms of design compared with silkscreen. If you want a mulitcoloured design, a screen will have to made for each colour, hiking up set up fees and labour. With DTG, you can be very creative with your design and have a much wider choice of colours (barring specialist colours such as gold and fluorescent). For white clothing this makes it perfect to print photos or designs with a lot of gradients.

DTG can also print on a variety of textiles including t-shirts, teatowels and sweatshirts.

Great For…

DTG can be used for a variety of reasons, here are just some great examples of stuff we’ve done in the past:

- Band merchandise

- Staff uniform

- Leaver’s hoodies

- Custom one-off clothing for gifts

- Stag/Hen clothing

- Fashion Brand

Get In Touch

If you are unsure about whether DTG is suitable for your job, want to find out more or see what other options are available please get in touch. Our helpful staff can talk through what you need!

Telephone – 01494 853 150

Email – sales@tee-tree.co.uk

Recent Comments